Product Code: 1220

Availability: In Stock

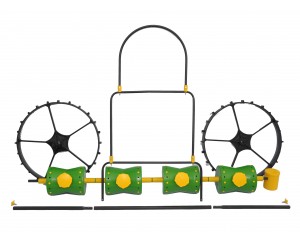

DIRECT PADDY SEEDER is one of the revolutionary equipment that changed the face of sowing paddy seeds in wetland fields. Direct paddy drum seeder has eliminated the need for transplantation and hours of manual work, which will literally break the backs of the farmers involved in sowing the paddy seeds into the field. At one stretch, with a single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. It is made up of plastic material, which makes it easy to carry.

DIRECT PADDY SEEDER is one of the revolutionary equipment that changed the face of sowing paddy seeds in wetland fields.

DIRECT PADDY SEEDER is one of the revolutionary equipment that changed the face of sowing paddy seeds in wetland fields. Direct paddy drum seeder has eliminated the need for transplantation and hours of manual work, which will literally break the backs of the farmers involved in sowing the paddy seeds into the field. At one stretch, with a single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. It is made up of plastic material, which makes it easy to carry.

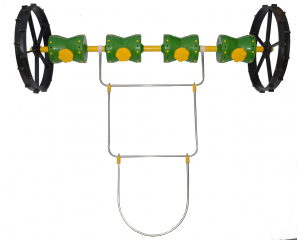

PARTS OF THE DRUM SEEDER:

1. The seed drum is hyperboloid shaped with a 200 mm diameter. There are eight seeding metering holes of 9 mm in diameter. Baffles are provided inside the seed drum between the seed holes to ensure a uniform seed rate in operation as well as to ensure hill dropping of the seeds. Each seed drum has two rows of planting, and four drums are assembled to form eight rows of planting in a single stretch.

PREPARATIONS:

1. Pudding should be well prepared and leveled.

2. Water should be drained out at least 24 hours before sowing to form a hard slurry pan of the puddled soil.

3. At the time of sowing, only paper-thin layers of water should be maintained in the puddled field.

4. Only just sprouted seeds packed in gunny bags should be used.

5. Water should be flooded into the puddled field once every three days after sowing and drain out immediately. This practice should continue for 12 days. Thereafter, depending upon the height of the seedlings, water should be allowed to stand in the field.

OPERATION PROCEDURE:

1. Assemble the paddy seeder and tighten all the bolts and nuts.SALIENT FEATURES:

| Specification | |

|---|---|

| Row to Row Spacing | 20 cm |

| Number of Rows | 8 |

| Diameter of Wheel | 60 cm |

| General | |

| Shape of Seed Drum | Hyperboloid |

| Area of Coverage | One hectare per day |

| Seed Requirments | 10 Kg per acre |

| Packing | |

| Packing Box Size | 66 x 66 x 36 cm |

| Machine Weight | 10 Kg |

DIRECT PADDY SEEDER is one of the revolutionary equipment that changed the face of sowing paddy seeds in wetland fields. Direct paddy drum seeder has eliminated the need for transplantation and hours of manual work, which will literally break the backs of the farmers involved in sowing the paddy seeds into the field. At one stretch, with a single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. It is made up of plastic material, which makes it easy to carry.

| Specification | |

|---|---|

| Row to Row Spacing | 20 cm |

| Number of Rows | 8 |

| Diameter of Wheel | 60 cm |

| General | |

| Shape of Seed Drum | Hyperboloid |

| Area of Coverage | One hectare per day |

| Seed Requirments | 10 Kg per acre |

| Packing | |

| Packing Box Size | 66 x 66 x 36 cm |

| Machine Weight | 10 Kg |

The Paddy Weeder, also known as a drum seeder or cono weeder, is a specialized agricultural implement designed to remove weeds from paddy fields. It consists of a seed drum, main shaft, ground wheel, floats, and a handle. The seed drum dispenses paddy seeds while the floats prevent sinking and facilitate easy pulling of the weeder. This tool is available in various configurations, including different row spacing options and seed metering hole sizes.

A paddy seeder is a transformative agricultural implement that has significantly improved the efficiency of rice cultivation. This advanced technology not only simplifies the planting process but also offers several advantages, making it a valuable asset for modern farmers.

One of the key advantages of using a Paddy Weeder is the significant labor and time savings it offers. Traditional manual weeding requires a large number of workers to remove weeds manually, which can be both physically strenuous and time-consuming. With a Paddy Weeder, a single operator can cover a larger area in a shorter period. This allows farmers to allocate their labor resources more efficiently and focus on other important farming tasks.

Investing in a Paddy Weeder can result in long-term cost savings for farmers. By reducing the need for manual labor, farmers can save on wages and reallocate those resources to other areas of their farming operations. Additionally, the use of a Paddy Weeder eliminates the need for chemical herbicides, which can be expensive and have negative effects on the environment. The initial investment in a Paddy Weeder can be quickly recouped through increased productivity and reduced weed control costs.

The Paddy Weeder is designed to efficiently remove weeds while minimizing damage to the crop plants. The adjustable row spacing and seed metering hole sizes allow for precise weed control, ensuring that the crop plants receive sufficient space and resources to grow. This targeted approach reduces competition between weeds and crops, resulting in improved crop health and higher yields.

Weeds not only compete with crops for nutrients, water, and sunlight but can also harbor pests and diseases. By effectively removing weeds with a Paddy Weeder, farmers can prevent the spread of pests and diseases, resulting in healthier crops. Additionally, the improved airflow and reduced humidity between the crop rows promote better ventilation, reducing the risk of fungal diseases.

While the Paddy Weeder is primarily used for weed control in paddy fields, it can also be used for other crops that have a similar row spacing and growth habit. Some crops suitable for paddy weeding include maize, soybeans, millets, and various vegetable crops. The Paddy Weeder's versatility makes it a valuable tool for farmers cultivating multiple crops in their fields.

Before using the Paddy Weeder, the field should be properly prepared. This includes plowing, leveling, and removing any large obstacles or weeds. The field should also be adequately irrigated to ensure the soil is moist but not waterlogged.

The Paddy Weeder should be adjusted according to the desired row spacing and seed metering hole size. This can be done by following the manufacturer's instructions and using the appropriate settings on the weeder.

To effectively remove weeds, the Paddy Weeder should be pulled in a straight line along the rows of the crops. The operator should maintain a steady pace and ensure that the weeder covers the entire width of the row. Care should be taken to avoid damaging the crop plants while removing the weeds.

After each use, the Paddy Weeder should be thoroughly cleaned to remove any debris or plant material. Regular maintenance, such as lubricating moving parts and replacing worn-out components, should be performed to ensure optimal performance. The weeder should be stored in a dry and secure location to prevent damage.

Regularly inspect the Paddy Weeder for any signs of damage or wear.

Adjust the weeder's settings based on the specific crop and weed conditions.

Monitor the field regularly for weed growth and schedule timely weeding operations.

Familiarize yourself with the local weed species and their life cycles to optimize weed control strategies.

Follow proper safety precautions while operating the Paddy Weeder, including wearing protective gear and using the tool in a well-ventilated area.